Amada Combination Servo Punch Press & Fiber Laser System

Model: EML2515-AJ 3kW / 33 TNF

Plus: Amada Automation Twin Tower 16 Shelf Load + Robotic Part Picking, Sort & Stack System

Model: ASR3015N+ULS3015N-TKPK

Plus: Amada Nitrogen / High Pressure Air System

Model: Amada EZM-1500A / 75 HP

This system was purchased new and installed in 2021.

Due to company closure, this system is available for immediate sale.

Replacement cost as equipped US$ 1,980,000.

Beam on time only 480 hours and Punch process time only 815 Hours.

Under manufacturer warranty throughout, with an AMP PLUS contract.

The Company’s Amada trained operator has 25 years’ experience on a C02 laser and 2 years’ experience on this Fiber Laser is available for employment subject to mutually agreeable terms.

We are currently welcoming and receiving offers.

Please submit your highest and best offer no later than Thursday March 16 however please note offers may be accepted before then.

Available for inspection in Toronto, Ontario, Canada upon request.

For additional information please contact:

Paul Golec 847-924-2226 or paul@mfogroup.com

Joshua Sugar 416-587-0237 or sugar@workingmancapital.com

Complete Specifications:

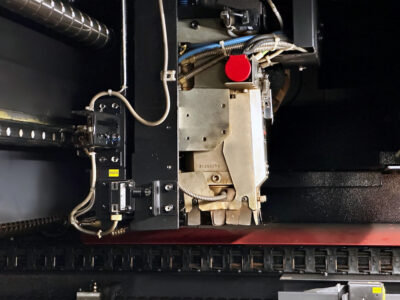

Amada EML2515-AJ 3kW / 33 TNF Combination Servo Punch Press & Fiber Laser System

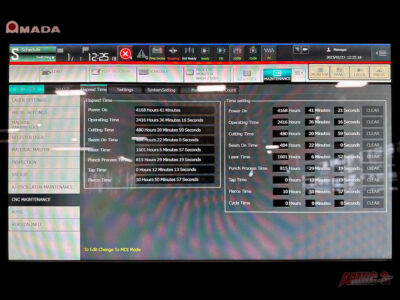

System Stats:

System Build Date: 2020

System Install Date: 2021

Operating Time: 2,416 Hours

Beam On Time: 480 Hours

Punch Process Time: 815 Hours

Specifications:

Punching Force: 33 Tons

Punching Operation (X/Y): 120” x 60”

Laser Operation (X/Y): 100” x 60”

Combined Working Area w/ Repositioning: 60” x 120”

Z Axis Laser: 14.9”

Maximum Material Thickness: .250”

Table Loading Weight: 480 Lbs.

Traverse Speed (X/YP): 3.937/3.149 IPM

Laser Axis (YL): 3,149 IPM

Axis Simultaneously: 5,031 IPM

Z Axis Simultaneously: 2,362 IPM

Punching Accuracy (Amada’s Punching Pattern): +/-0.0027”

Assist Gas Change: Automatic

Included Rotation Stations: 4

Stroke (Adjustable to suit application): 1.5”

Punch Rate (On I” centers): 500/min.

In Marking Mode: 1850/min.

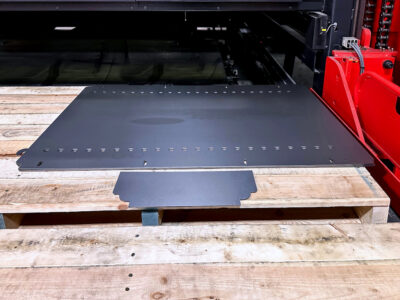

Table Design: Brush Table

Parts Chute: 15.75” x 60”

Machine Frame: Bridge Frame

Press Drive: Servo Electric Drive

Turret /Table Drive: AC Servo Motors

Machine Weight: 33 Tons

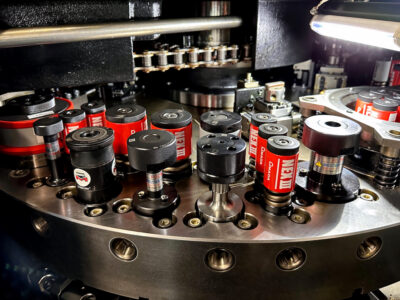

Tool Stations: 55

Continuous Laser Output: 3 KW

Type: AJ 3000 Fiber

Control: AMNC 3i

Storage Capacity: 440kB

Number of Controlled Axes: 6

Equipped With: Punch / Laser Combo

Amada Multi-Touch AMNC 3i Controller

Bar Code Reader

3KW AJ Fiber Engine

Auto Nozzle Cleaner & Changing Station

33 TNF (US) Dual AC Servo Ram Drive

55 Station MPT Triple Track Turret

Nylon Brush Table

Punch & Form Feature

4 Tapping Stations

Air Blow

Power Vacuum Die

Automatic Work Chute

Scrap Conveyor

High Density Nylon Brush + Pneumatic Roller Ball Table

Interlocked Perimeter Safety Guarding

Transformer Unit (75 KVA)

Integrated Chiller System

Camfil Gold Series X-Flow GSXP Dust Collector

Punch Tooling Package ($45,000)

Punch Tooling Cabinet

Automation:

Amada ASR3015N+ULS3015N-TKPK – 16 Shelf Load / Un-Load Automation + Robotic Part Picking, Sort & Stack System (Twin Tower)

Nitrogen / High Pressure Air System:

Amada EZM-1500A / 75 HP Nitrogen Generation Assist Gas / High Pressure Air System (N2 Gen w/75 HP Comp, 2000 SCFH @ 99% pure – 5000 SCFH @ 95% pure, 1800 SCFH Dry Air Assist Gas, 205 PSI delivery, 600 Vac 3PH) Includes Transformer

Additional Items Included:

Sick Safety Light Barriers

Perimeter Safety Guarding

OEM Shipping Brackets

Full Set of OEM Operating Manuals

Laser & Turret Spare Parts

Laser Consumable

Nitrogen / High Pressure Air System Spare Parts

Nitrogen / High Pressure Air System Consumables