*NOTE NEW DATE, NOW ENDING MARCH 20, 12PM ET

Surplus to the ongoing operations of Aleafia Health

Online Timed Auction Ending: March 20, 12pm ET

Inspection: By Appointment Only

Winterization Skid System Addresses:

Main Skid: 20 Woodslee Ave, Paris, Ontario N3L3N6

Additional Crates: 2560 Shirley Road, Port Perry, Ontario, L9L1B3

CO2 Extractor Address:

- Ashley Street, Hamilton, Ontario, L8L1V8

Featuring:

Winterization Skid System (by Stainless Piping Systems)

Original Cost Over $1,200,000 (2020)

Skid (green item in image below) was installed in 2020, used only minimally for testing purposes only. Was assembled in clean room, requires some disassembly for removal.

Remaining items are still in original crates in storage.

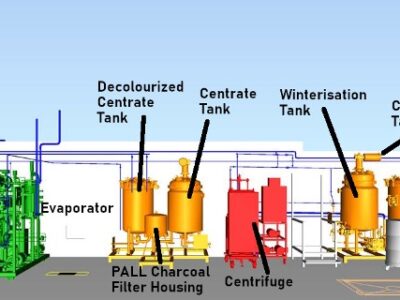

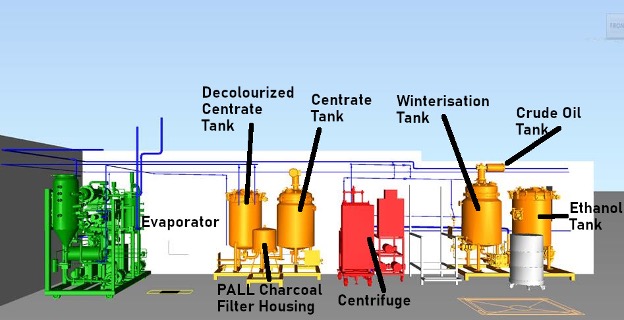

The winterisation skid was designed to heat 240L of an ethanol/cannabis resin solution from 20C to 60 C in 90 minutes, followed by cooling of this solution to -40C in 120 minutes in the Winterization Tank. Approx capacity of 40 kg per 8 hour shift.

Ethanol is supplied to the skid’s Ethanol Tank via a 210L drum that is fit with a bung that allows for N2 inert atmosphere to blanket the ethanol.

Cannabis resin is supplied via a 15L Crude Oil Tank that is connected using a flexible hose into the Winterisation tank. Ethanol is transferred from the Ethanol Tank through the Crude Oil Tank via air diaphragm pump.

Subsequent Centrifugation of the cooled ethanol/cannabis solution is designed to strip the insoluble waxes from the solution. The centrifuge unit has a specified throughput of 1.5 LPM (assuming bulk material density of 1.5 g/mL). The centrifuge is jacketed and cooled to -40C.

Outflow from the centrifuge is transferred into the Centrate Tank. The Centrate tank is jacketed and heated to 20C (facility supplied water/glycol). Using N2 overpressure the contents of the Centrate tank are transferred through the Charcoal Filter and then into the Decolourized Centrate Tank. (This charcoal filtering step is optional and can be bypassed).

The contents of the Decolourized Centrate tank is then transferred to the evaporator (not part of the skid) using the evaporator pump.

Cleaning of the system is performed in place (CIP) using ethanol.

The entire system is enclosed to prevent exposure of ethanol to the atmosphere and includes overpressure with nitrogen gas (supplied from facility) and remain C1D2 compliant.

Hundreds of pages of documentation and specifications available upon request.

Super & SubCritical CO2 Extractor (by Pure Extraction)

Original Cost Over $150,000 (2018)

Only used minimally for testing purposes, less than approx. 100 hours. Note: Owned by third party (not Aleafia)

System overview of Pure Extraction Closed Loop Botanical Oil Extractor

The process of subcritical or supercritical CO2 extraction is changing the phase of CO2 into a 4th stage (supercritical) other than solid, liquid or gas. Using CO2 as a solvent in order to dissolve the plant oil when it is in supercritical state and releasing the oil when that state is turned into gas. Each of the 3 steps of extraction is meant to change the phase of the CO2.

Oil extractor has 3 main systems that operate together to ensure closed loop subcritical and supercritical extraction of botanical oil

- Liquid CO2 pump to pressurize and create flow of CO2

- Back pressure regulator, to adjust pressure of pump outlet

- Pre heater w controls to increase pressurized CO2 to extraction temp

Extraction vessel hold the material to be extracted

Extraction heater w controls, vessel heater to maintain extraction temperature

Separation metering valve, to reduce extraction pressure to separation pressure

(2) Separators w heaters, controls, collection vessel w heaters for raw oil

Separator filter w paper filter

Closed loop string to condensate gaseous CO2 into liquid CO2 through chilling the gas

Glycol chiller for both heat exchangers

Condensing heat exchanger after separation string to liquify CO2

Liquid CO2 storage tanks, storage and buffer tank for liquid CO2

5 Litre Extraction System

Max vessel size 1 x 5L, scalable, can be dual system

Max pressure 3,000 psi

Operating temp 10 – 50 deg c

Dimensions 72 x 33 x 60 in

Weight 900 lbs

Power 220 VAC/50A/1PH

Chiller System

Max vessel size 25 gallon (oversize, can run 2-3 systems)

Max pressure 30 psi

Operating temp -8 – 0 deg c

Dimensions 55 x 24 x 65 in

Weight 700 lbs

Power 220 VAC/24A/1PH

All information is provided by the clients or owner manuals, we believe all components are intact, as always, we urge all buyers to inspect prior to purchase to satisfy themselves.